The STRIEBIG STANDARD – the world's best-selling vertical panel saw

The STANDARD S complements this success story. It combines proven technology with new technology. With the two versions TRK1 and TRK2, as well as the recommendable equipment with the attractive Comfort Package, it offers a wide range of possibilities.

STANDARD S: two versions, many possibilities

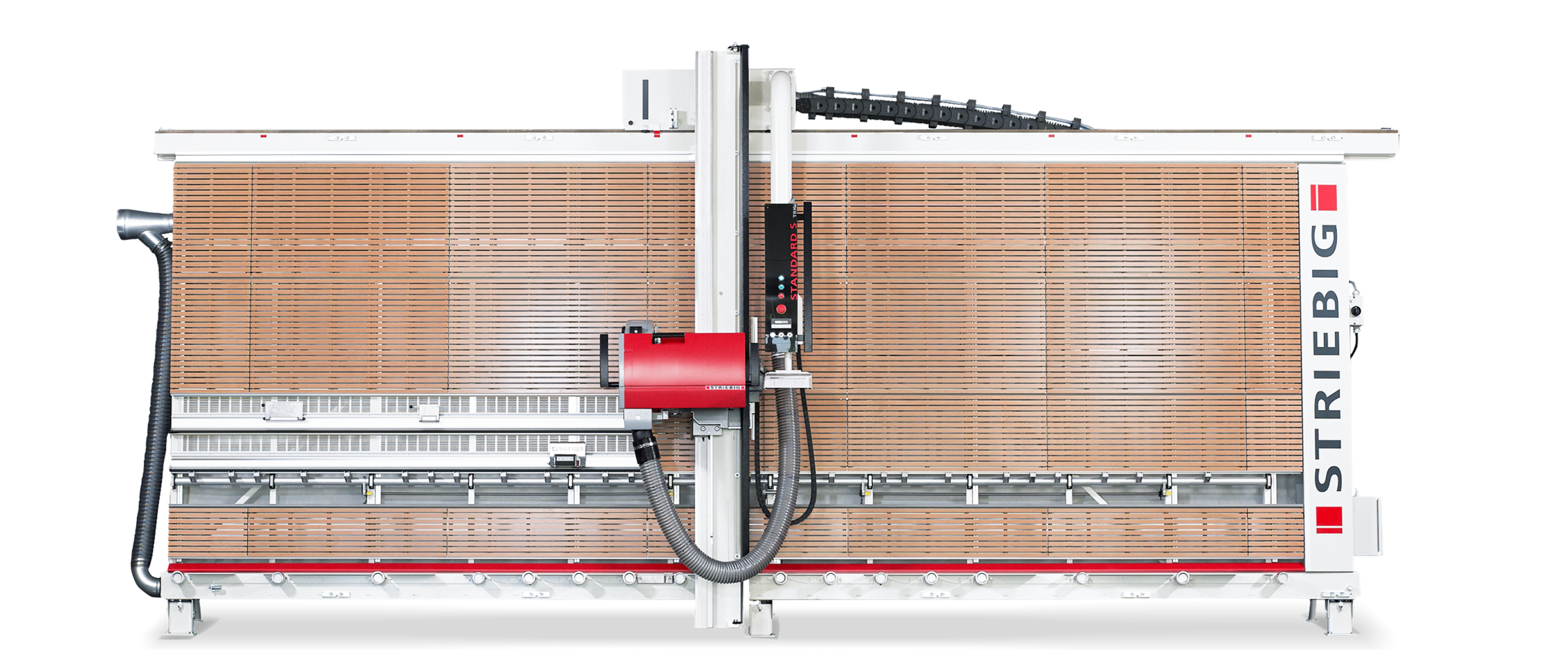

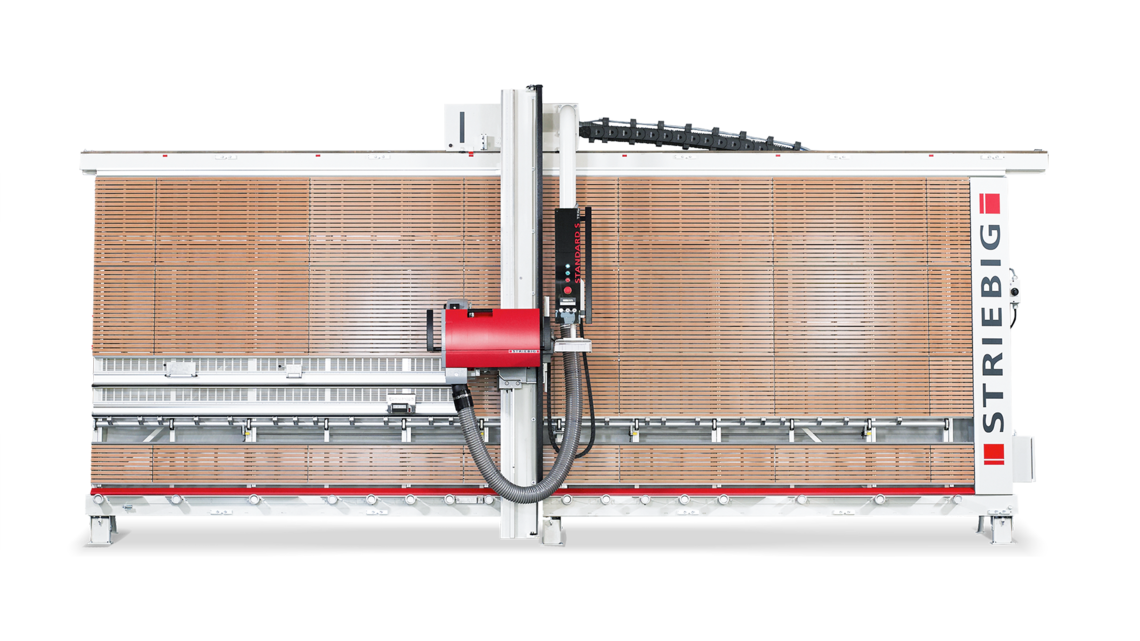

STANDARD S TRK1

With automatically yielding wooden support wall.

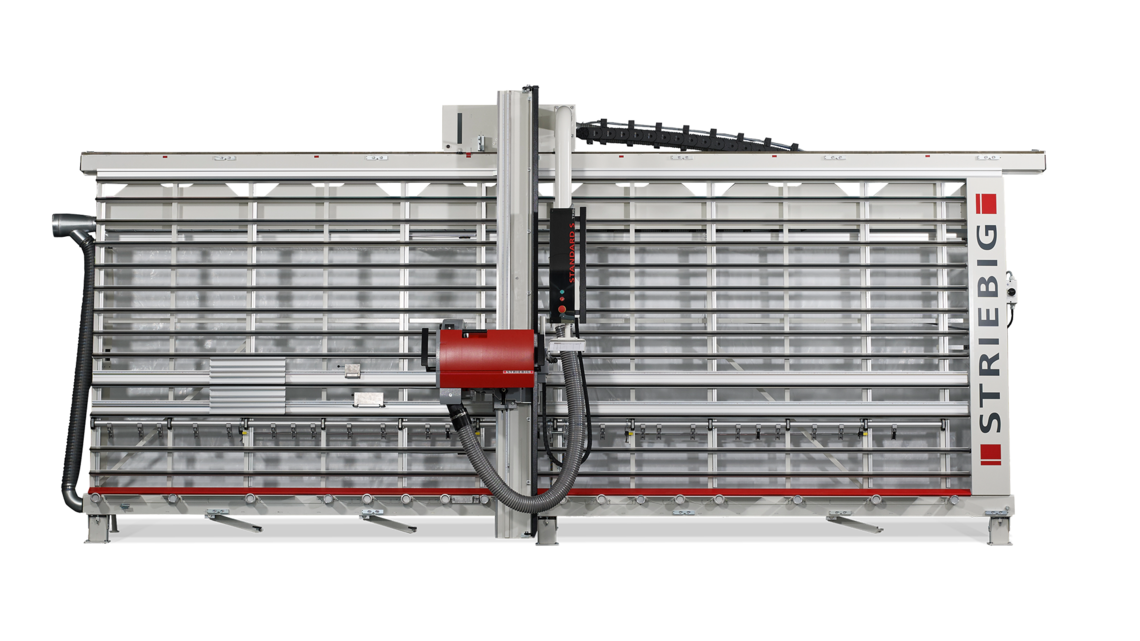

STANDARD S TRK2

With automatically yielding aluminium slatted frame.

STRIEBIG STANDARD S (video)

Highlights of the STRIEBIG STANDARD S

The legend lives on, the name is a pledge

The STANDARD S adds another chapter to the STRIEBIG success story. Highest quality of the processed materials as well as easy handling are guaranteed with the STANDARD S.

Versatility meets pedigree

With the STANDARD S we are opening up a new dimension to the benefits for hand-guided sawing.

Two versions, a Comfort package with extended basic configuration and over 20 additional options and accessory components take the STANDARD S to a new level.

Precision thanks to stability

Self-supporting, welded and rigid, the saw frame is the heart of every STRIEBIG panel saw.

Upper guide rail, central support and roller support are perfectly parallel to each other. This guarantees you many years of cutting precision and a high-level of investment security.

Comfort package

The recommended Comfort equipment (optional)

- Pneumatic clamping of the motor carriage

- Digital measuring system DMS-Y, incl. fine adjustment

- Pneumatically braked support rollers

- Laser-supported display of the horizontal cut

The universal vertical saw

Precision meets comfort. Functions of the STANDARD S have been consistently expanded. With this woodworking machinery, hand-guided saws reach a new dimension of use.

Comprehensive standard equipment

- Solid, self-supporting, welded, rigid saw frame

- Sturdy, durable saw beam steel construction

- Robust bearing of the motor carriage ensures high cutting precision

- Powerful, high-torque 5.5 kW motor (7.5 HP)

- TRK dust extraction

- Model TRK 1 with automatically yielding wooden support wall

- Model TRK 2 with automatically yielding aluminium slatted frame and plastic supports

- Device for wall mounting

- 17-fold roller support with 3 brake pedals (model 6224)

- Integrated cutting gauge for horizontal strip cuts (500 mm)

- Program cam button for recurring dimensions

- Small workpiece supports (Alu), 2 pair, individually applicable (only model TRK2

without small workpiece supports wood) - Super-silent noise insulation to reduce saw blade noise

- Electromagnetic motor brake

- ProLock easy-fix tool clamping system

| Weight of the saw | approx. 1.100 kg |

| Cutting depth | 80 mm |

| Saw motor power | 5.5 kW (7.5 HP) |

| Saw blade diameter | 300 mm |

| Saw blade bore | 30 mm *1 |

| Emission sound pressure level at the workplace LpA | 83 dB *2 |

| Saw blade speed | 4800 rpm |

| 1 extraction connection | ø 140 mm |

| Compressed air connection | 6-10 bar *3 |

| Wattage | 7.3 kW |

| Mains connection | 3 x 400 V / 50 Hz |

*1 with 2 side holes Ø 9 mm, radius 30 mm · *2 measurement standards and emission values in accordance with EN 1870-14, measurement uncertainty allowance K = 4 dB (A). *3 Compressed air connection only required for options (all specifications refer to the STANDARD S Type 6224)

For all machines:

Powerful TRK dust extraction significantly below 2 mg/m3. The system used must have an extraction performance of 20 m/s in order to meet the TRK specifications. (Vacuum approx. 1400 Pa. / COMPACT approx. 1470 Pa) at the connector in order to meet the TRK specifications.

Technical note:

Permissible ambient temperature min: + 5 °C / max. + 40 °C

Relative humidity: 19 - 95% without condensation

In case of mains fluctuations greater than +/- 10% of the nominal voltage, a voltage stabiliser must be installed at the place of use.

The technical specifications are approximate values.

We reserve the right to make changes due to further developments.

Dimensions in mm

| Type | L* | H | T1 free |

T2 Wall |

|---|---|---|---|---|

| 6224 | 6626 | 3055 | 1766 | 1383 |

| 6216 | 6626 | 2971 | 1730 | 1376 |

| 6168 | 6626 | 2497 | 1525 | 1334 |

| 5224 | 5626 | 3055 | 1766 | 1383 |

| 5216 | 5626 | 2971 | 1730 | 1376 |

| 5168 | 5626 | 2497 | 1525 | 1334 |

| 4224 | 4626 | 3055 | 1766 | 1383 |

| 4216 | 4626 | 2971 | 1730 | 1376 |

| 4168 | 4626 | 2497 | 1525 | 1334 |

* L = Total length of the machine

Cutting area in mm

| Type | LS | HS vertical |

HS horizontal |

|---|---|---|---|

| 6224 | 5300 | 2240 | 2100 |

| 6216 | 5300 | 2160 | 2016 |

| 6168 | 5300 | 1680 | 1540 |

| 5224 | 4300 | 2240 | 2100 |

| 5216 | 4300 | 2160 | 2016 |

| 5168 | 4300 | 1680 | 1540 |

| 4224 | 3300 | 2240 | 2100 |

| 4216 | 3300 | 2160 | 2016 |

| 4168 | 3300 | 1680 | 1540 |

Configure STRIEBIG STANDARD S

Simple, online and individually tailored to your needs: Configure your very own STRIEBIG STANDARD S.