Flawless transfer of parts to ongoing production processes

Käslin Innenausbau AG has been manufacturing high-quality furniture and kitchens in Steinhausen (CH) since 1969. In earlier years, cut-to-size parts were written on using adhesive tape and felt-tip pens and then passed on to further processes in the company. After the introduction of an ERP system, labels were printed on A4 sheets in the office, but this was tedious in production due to manual searching and detaching. Today, STRIEBIG OptiDivide takes on these tasks, making cutting much easier.

Modern production means for high vertical integration level

«We want to carry out all manufacturing processes directly in our own workshop. If we could no longer produce, I would stop», says Lukas Käslin, owner and managing director of Käslin Innenausbau AG since 1997, describing his motivation for investing in new machines. The new STRIEBIG is already the third vertical panel saw from Lucerne that the company has put into operation. Lukas Käslin's motives for purchasing the new STRIEBIG are diverse: outstanding quality, ideal price-performance ratio, top service and strong brand identification.

Consistent final cut with the new STRIEBIG EVOLUTION

«Thanks to the fact that a label with all relevant information is printed out on the operator terminal simultaneously as a part is cut makes work much easier. In conjunction with the scoring saw unit, we were able to adapt to a consistent finish cut, which also accelerates the production process,» explains Beat Marty, production manager and member of the management team.

Beat Marty

production manager and member of the executive board

A reduced workload brings an increase in efficiency

Käslin stands for interior fittings, kitchens and furniture of the best quality. Josef Käslin laid the foundation stone for the company back in 1969, and Käslin Innenausbau AG developed from this under the management of Lukas Käslin. For Lukas Käslin it is important that he creates a varied working environment for his 15 employees, five of whom are apprentices, so that everyone feels comfortable and enjoys coming to work. Qualified employees with a high level of expertise are crucial for advice, planning, implementation and service. In addition to young specialists, Käslin AG also has long-term employees with lots of experience. For example Thomas Betschart (Deputy Managing Director), who has been contributing his specialist knowledge to the company for 32 years now and, as a project manager, also prepares production orders.

Thanks to the integration of the intelligent STRIEBIG cutting optimisation in the work preparation of Käslin AG, a continuous flow of data in the production process can now be guaranteed. The parts lists created in the industry ERP or CAD system are exported as Excel CSV files, transferred to the STRIEBIG cutting optimisation software and optimised at the office workstation for optimum cutting on the STRIEBIG EVOLUTION. By connecting the STRIEBIG OptiDivide to the network environment via WLAN, the optimised cutting jobs are available to the operator directly on the STRIEBIG. This makes work easier and leads to efficient cutting.

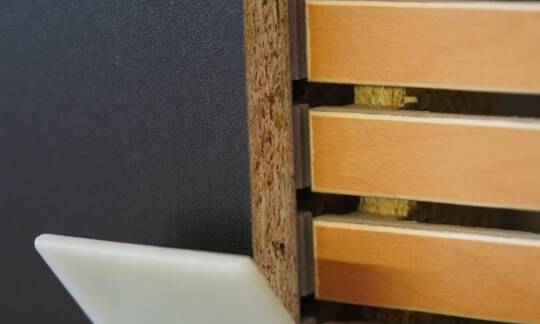

The new STRIEBIG EVOLUTION is in daily use at Käslin Innenausbau AG and is mostly at the beginning of the manufacturing process. "That is why it is an important and central machine in the entire process of our own production," says Lukas Käslin. All common wood-based materials are processed, but mainly coated and raw chipboard as well as coated and raw MDF boards. «Thanks to the good cutting quality and the time saved by printing labels directly on the machine, the investment in the new STRIEBIG EVOLUTION has paid off. My gut feeling was good right from the start and this decision has been confirmed », Lukas Käslin adds with satisfaction.