Cut optimisation boosts satisfaction

Boissec AG from Bussigny, Switzerland, sees dramatic improvement in panel cutting with a new STRIEBIG CONTROL with ExpertCut cut optimisation. Customers have greatly valued this service for years. It is enjoying increasing popularity.

The focus is on quality and Swiss origin

Domestic products and producers are preferred wherever possible, and panel materials are almost 100 percent Swiss Krono. Boissec AG from Bussigny in the canton of Vaud exclusively supplies specialised companies and custom panel cutting is an important service in their portfolio.

“We intend to expand this service even further and work more flexibly. We have installed a new STRIEBIG CONTROL with ExpertCut Con cut optimisation to be perfectly equipped for this,” explains Deputy Director Camille Allaz.

Highest Customer Satisfaction

“Opting for both saw and software package was the right thing to do. A tear-free cut and absolute angular and dimensional accuracy are important quality criteria for our customers. The CONTROL guarantees this 100 percent. We’ve already received plenty of positive feedback from our customers for these properties.”

Camille Allaz

Deputy Director of Boissec AG, has already received a lot of positive feedback.

Continuous data flow

With its new operator HMI and the installed software package, the CONTROL greatly reduces the work involved in cutting. For the use of ExpertCut, it comes equipped as standard with the electronic positioning system EPS.x and the automatic saw beam positioning ASP. An inte§cutting. The operator positions the saw unit and longitudinal stop at the press of a button.

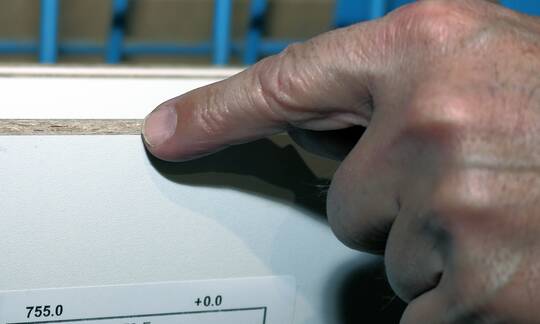

Labelling and precision

With its new operator HMI and the installed software package, the CONTROL greatly reduces the work involved in cutting. For the use of ExpertCut, it comes equipped as standard with the electronic positioning system EPS.x and the automatic saw beam positioning ASP. An intelligent visualisation takes the operator step by step through the work process of cutting. The operator positions the saw unit and longitudinal stop at the press of a button.

The CONTROL automatically processes the defined dimensions. The label printer of the saw prints a label for identifying the workpiece directly during cutting. All the operator has to do is remove the cut workpiece and stick on the label. Done. The cut piece is unambiguously labelled, mix-ups are ruled out. Cut by cut, the CONTROL continuous to work through the optimised cutting list.